Alien

Rated 0 out of 5

$79.00

Select options

This product has multiple variants. The options may be chosen on the product page

Incense sticks are incense without a bamboo core, also known as straight incense or herbal incense. They are made up of materials such as aggregates, binders, fragrances, pigments and auxiliaries.

Incense appeared as early as the Song and Ming dynasties, and was especially loved by the aristocracy and literati. It was a daily necessity for maintaining health and cultivating sentiment at home.

Because incense burns for a relatively long time, it is also known as “immortal incense” or “longevity incense”. In ancient times, temples commonly used the length of incense as a unit of time measurement, so it was also called “incense inch”.

There are many benefits to lighting incense in your daily life.

The aroma soothes the mind and helps you sleep, clears the mind and regulates the flow of energy, relieves coughs and asthma, nurtures the body and mind, and purifies the home.

So, how are incense sticks made?Today, we will take a look at the process and procedure of making incense sticks.

The choice of materials is an important part of making incense, as the quality and purity of the materials directly affect the quality and effect of the incense. Raw materials need to be carefully classified according to their place of origin. Next, we will use agarwood incense sticks to explain in detail.

To produce high-end agarwood incense, it is advisable to select fragrant materials with clear oil lines, thick and full knots, and rich layers of fragrance. Yufeng agarwood chooses natural knots from mature agarwood trees that have been growing for 20 years, which bring a fruity aroma, a honeyed sweetness, and a sense of luxury to the incense, as well as a clear and refreshing charm.

Remove any soil, rotten skin or other impurities from the agarwood. The cleaner the raw material, the purer the incense’s flavor and the higher its quality.

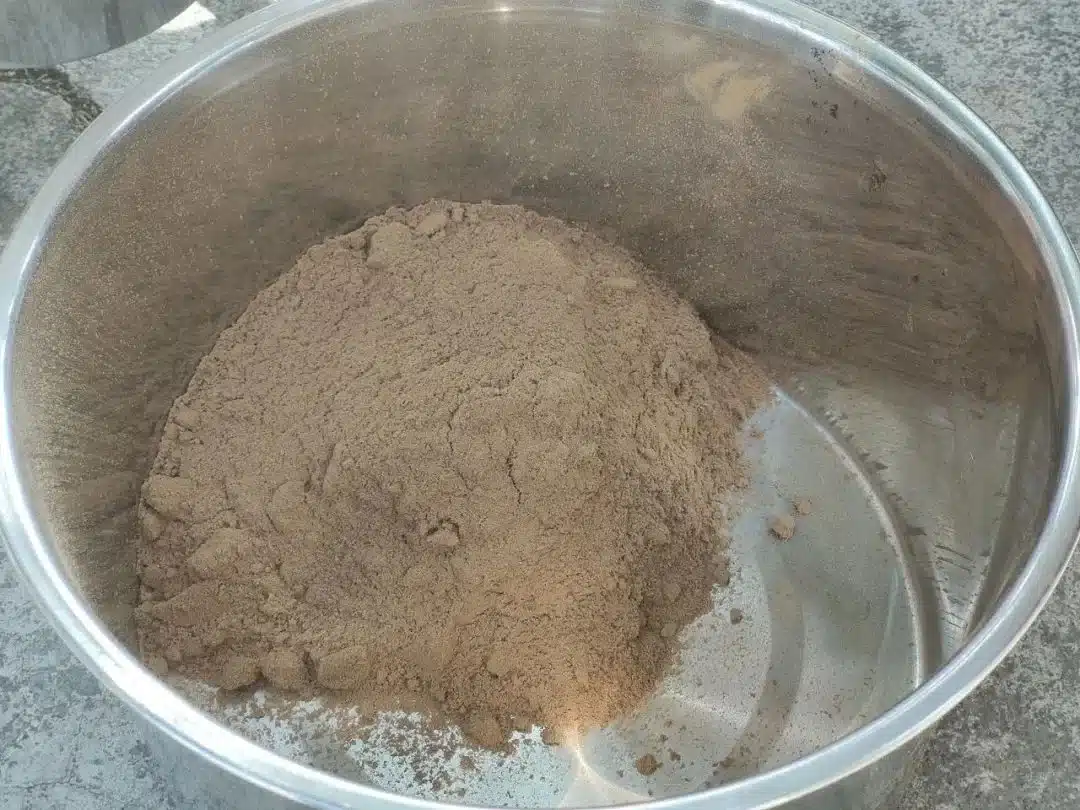

One of the important steps in making incense is to put selected pieces of agarwood into the machine and grind them into a fine powder.

Different fragrances have different requirements for the fineness of the fragrance powder. Not all types of fragrance powder are better when they are finer. Sometimes the size of the fragrance powder particles can also affect the fragrance.

Use a sieve to filter out the coarse particles in the agarwood powder, leaving behind a fine and even agarwood powder. Sifting the powder helps to improve the overall appearance of the incense, facilitates full and even burning of the incense, and thus enhances the fragrance experience.

A good incense stick has a delicate surface that is almost free of pits!

Heartanew exercises precise control over every aspect of its agarwood incense sticks.

Generally, the mesh count for ordinary sifted flour is 80 (that is, the mesh count for commonly used flour). In order to achieve the high quality standard of finished incense, we use a 100-mesh fine sieve to strictly sift the flour and polish it repeatedly, so that you can have the best incense-burning experience.

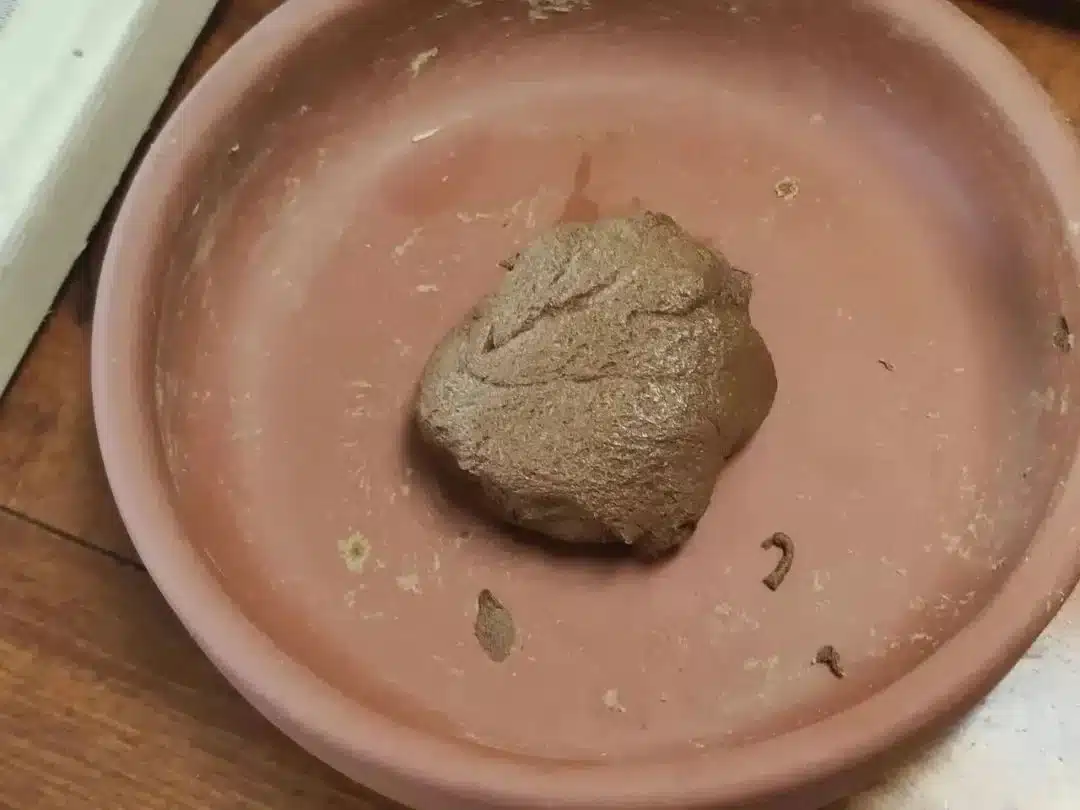

Mix the agar powder, vegetable glue powder and water in a certain ratio until well combined.

Among them, plant-based adhesive powder mainly serves the functions of shaping and combustion support. It is advisable to use natural elm or nanmu powder.

After dozens of trials, Heartanew finally adopted nanmu, a natural plant with the strongest viscosity, as the plant-based adhesive powder. It is 100% pure and natural, environmentally friendly, has a soft taste, and does not affect the natural flavor of the agarwood.

In addition, the ratio of various spices and ingredients used in incense making, too much or too little of which will affect the burning of the incense.

The ratios commonly used in the market are mostly between 80:20 or 85:15. With high-level incense-making techniques, the ratio of agarwood powder to plant-based adhesive powder can reach more than 90:10.

The less sticky powder there is, the purer the aroma of the incense. The more sticky powder there is, the more likely the incense will curl.

After the incense powder is synthesized, spring water and a natural binder are added and kneaded together to form an incense clay. The clay is then kneaded and beaten repeatedly to ensure that the various incense powders are thoroughly mixed and the texture of the entire clay is more compact, so that the finished incense will not break easily.

At present, our incense sticks are made using the highest level of incense-making craftsmanship, and can be made without additives and with zero powdered adhesives.

However, powdered-adhesive-free incense sticks are more likely to break than those with powdered adhesives.

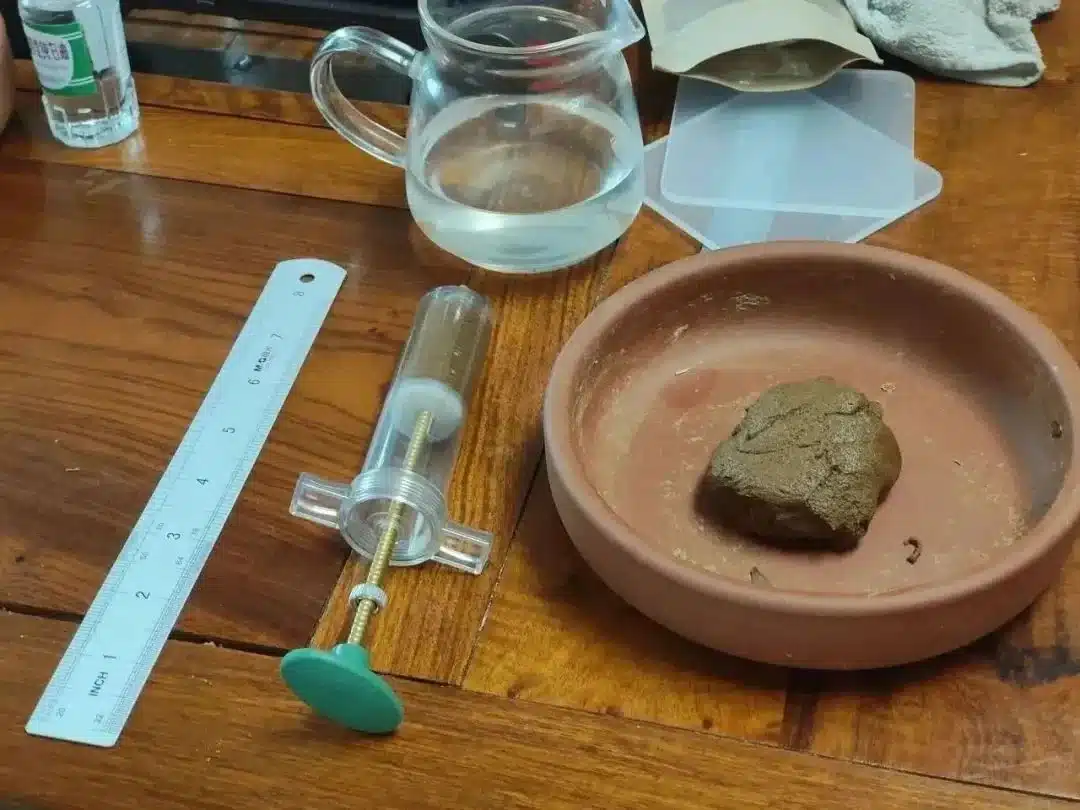

The mixed raw materials for wet incense are pressed into incense sticks through an incense stick machine.

Use a ruler to arrange the incense sticks neatly, cut them to the specified length, and cut them precisely. At this time, improper handling may cause the incense sticks to break, which is also a relatively wasteful process.

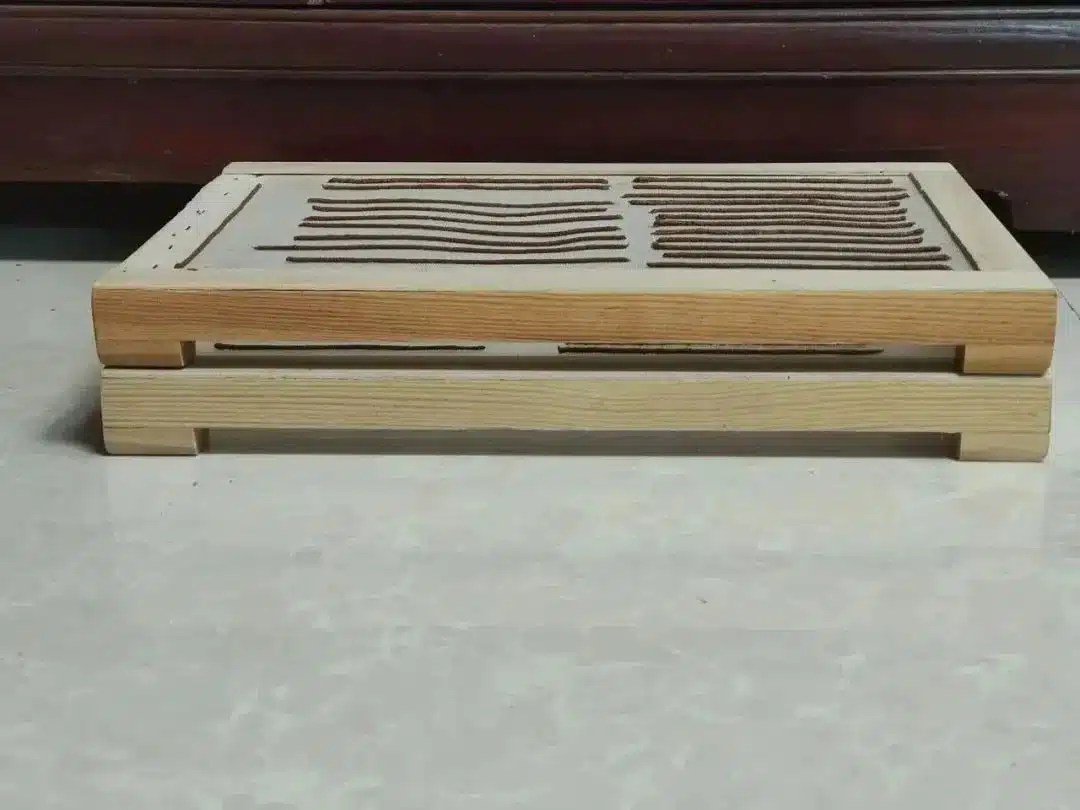

After forming the incense, it needs to be placed in a ventilated area to dry in the shade to remove excess moisture from the incense, which is beneficial for long-term preservation.

To prevent the incense from deforming during the drying process, a wooden frame is often used. A hemp rope is threaded through the middle of the frame, and the incense is placed on the rope to dry in the shade.

To ensure its quality, the aromatic materials can only be naturally dried in a ventilated area that avoids direct sunlight. This process usually lasts for a week to ensure that the spices can better achieve the desired effect.

After the incense has dried in the shade, the excess moisture is removed, and it needs to be stored in a place protected from light and with suitable humidity and temperature.

Generally speaking, 18-21°C is considered the ideal temperature for storing agarwood incense, as it allows the spices and medicinal herbs to better blend and work with each other, so that the aroma is both layered and integrated.

If it is higher than 28℃, it will cause the aroma of the agarwood to volatilize excessively, shortening its aroma life.

The relative humidity should preferably be kept constant between 65-75%.

After the incense is made, it is usually stored for 3 to 6 months to allow the agarwood to naturally mellow with time, get rid of the smell of smoke and fire, and facilitate long-term preservation of the incense. The powder used in a high-quality incense stick also needs to be stored for at least three years.

Incense that has been aged for a certain number of years smells even more mellow and rich. The taste of agarwood can only be appreciated after you have personally experienced it.

Weigh and pack. Incense packaging must be dry and shock-absorbent, as is required for storage. The container should also be easy to open and close at any time and easy to check the product.

After strictly following these 10 steps and carefully and attentively polishing and crafting the incense, the transformation from agarwood chips to incense is complete. It can be said that each incense stick is the essence of agarwood, reflecting the quality and rank of the incense.